2 Delaere mobile bigbag filling machines for Carbon Black

2 Delaere mobile bigbag filling machines for Carbon Black

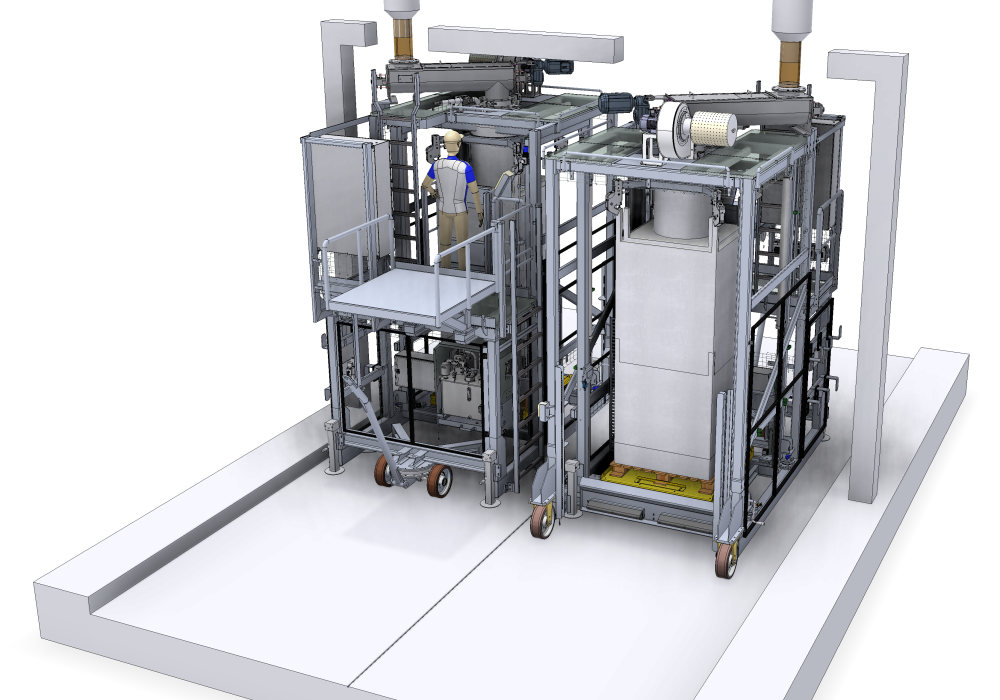

Delaere supplied 2 mobile bigbag filling machines for a Carbon Black producer in Indonesia. The filling machines are 1-position machines without pallet dispensers and roller conveyors. Typical filling capacities (output) that can be reached with this type of machine is 10 to 15 bigbags per hour of 1 Ton.

The 2 mobile bigbag filling machines are identical and are used in parallel under a double row of silos. Dosing of the product is done using a screw conveyor system equipped with a variable speed drive to enable coarse and dribble feed.

These compact machines don’t require a PLC system but are fully controlled through the weighing terminal.

The machines are equipped with a towbar connected to a swivel element. They can easily be moved using an FLT. 4 leveling feet and a bubble level are ensuring the correct functioning of the weighing system.

Challenge

A first major challenge was the request to enable the filling of single and double stacked bigbags. Delaere installed a EV2SR type filling station which is a gross weighing filling system with height adjustable laydown level for the empty pallet. Regardless of the height of the bags to be filled, the operator always stands at the same ergonomic height towards the filling pipe of the filling station. The first filled bigbag will be considered as tare weight before the filling of the second bigbag starts.

Due to space and height constraints inside the existing plant, the outline dimensions of the machines were a critical item. The width of the machine had to be limited so that both machines can move in parallel in the driveway under the silos and be able to overtake each other.

There was only a limited height available for the mobile bigbag machines. The machines are to be connected with the outlet of a movable safety sieve which is running on an intermediate platform and the machines had to fit under the steel beams of this platform. The filling station designed by Delaere has a short and fixed filling pipe which is consuming much less height compared to a classic telescopic system.

Because of a height difference in the elevation of the floor level, an off set had to be created of approx. 1000 mm between the outlet of the mobile safety sieve and the center of the mobile bigbag filling station. This was solved by means of a screw conveyor. The screw conveyor is equipped with a VSD to create coarse and dribble feed.