Delaere automatic sampling systems equipped with carrousel

Delaere automatic sampling systems equipped with carrousel

To control the quality of the product to be filled, Delaere can add an automatic sampling system to its bigbag and octabin filling systems.

These sampling systems can be integrated in the filling pipe of the filling station or in the upstream buffer/product hopper. Trough piping, the collected sample is guided towards a collection recipient which can either be a simple plastic bag or a sample bottle.

The sequence of the sampler can be programmed and selected in the recipe management system. Depending on customer requirements, it is possible to take one or several samples per bigbag or octabin to be filled or just one sample per batch.

Different types of Samplers

Delaere is able to offer different types of samplers for different type of products

The Diabolo sampler can be integrated in both the filling tube or in the upstream product hopper. During sampling, a “spoon” is pneumatically pushed forward in the product flow and is guiding the product sample towards the discharge pipe during its backwards movement. The Diabolo sampler is built in stainless steel 304 or 316 and is electro-polished to achieve a very smooth surface on the product contact parts. The moving parts of the Diabolo sampler are executed in the very high quality material PEEK which is also very resistive. The Diabolo sampler can be built in 2 different sizes to enable the sampling of powders and granulates but also larger product particle sizes such as cacao cake.

A screw sampler can be integrated directly in the Delaere dosing valve type Casque. A great benefit is that this sampling system is not consuming any additional height. During sampling, the screw is actuated by means of a pneumatic motor. The screw system is built in both stainless steel 304 or 316 and the pitch of the screw can be adapted depending on the product characteristics.

For fine powders, Delaere can propose its vacuum sampler. This vacuum sampler is integrated in the filling pipe of the filling station. By means of a venturi, vacuum is created and product is sucked out of the filling pipe. Trough a cyclone, the product is collected and falls in the discharge pipe towards the sample bag or bottle. The big advantage of this type of sampler is that there are no moving parts in the product flow.

Carrousel system

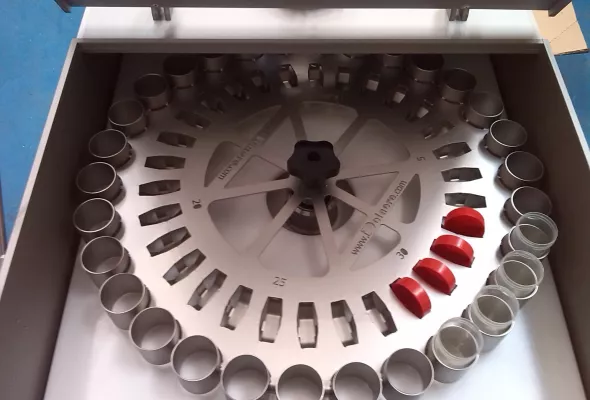

In a standard solution, the operator needs to place a new sample bag or sample bottle after every sampling cycle. To avoid this, the sample discharge pipe can be connected to a carrousel system in which several sampling bottles can be positioned.

Depending on the size of the sample bottles, up to 30 sample bottles can be stored in a rotating wheel installed in the housing of the carrousel system. The sample bottle to be filled, is lifted and pushed against a seal to assure a dust-tight connection. On the top of the housing of the carrousel system, also a filter system with F9 filter is installed to “catch” up flowing dust during filling of the sample bottle.

Once a sample bottle is filled, the rotating wheel will be actuated by means of a stepping motor. The aluminum housing of the carrousel system is equipped with a transparent cover and holds storage positions for the covers of the sample bottles.

Result

Delaere can offer different types of high performant sampling systems depending on the nature of the product, the required position and needed frequency of the sampling unit, the available height and level of automation.

Sequence and control of the sampling device are perfectly fine-tuned during commissioning phase of the Delaere equipment.