Innovative Plastic Bigbag and Octabin Packing Line

Innovative Plastic Bigbag and Octabin Packing Line

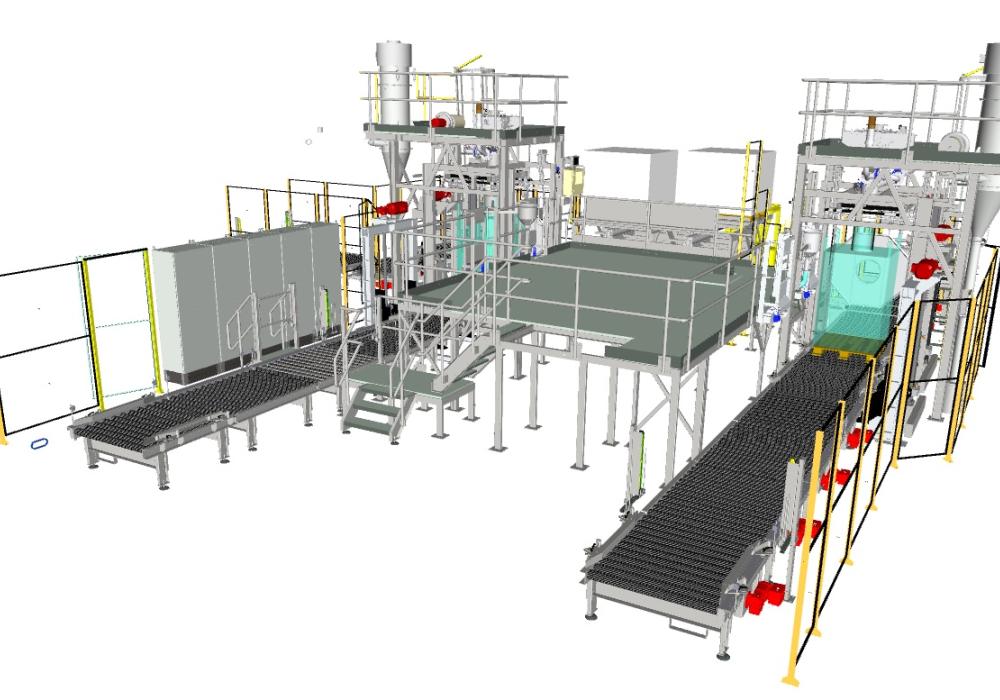

For a Innovative plastic compound producer in The Netherlands, Delaere has delivered a complex double bigbag/octabin filling line for packing 20 ton of plastics per hour per filling line in octabins. The batches to be packed have a limited volume and the customer is frequently switching between the different grades to be packed. The complete filling system is washable with water. Delaere developed a custom made dosing valve and filling tube for this project.

The following items were part of the Delaere scope of supply:

- Dedicated pallet dispenser and foil dispenser per bigbag/octabin filling line

- Separate infeed line for empty octabins

- 2 Bigbag/Octabin filling stations with incorporated octabin coverplate for filling of octabins with open mouth liner

- 2 Special filling tubes – Washable with water and dryable with an air heater

- 2 Special dosing valve for high speed dosing of granulates - washable with water and dryable with an air heater

- Shared working platform in between the 2 lines of approx. 35 m² - With slide-out plates for empty bigbags and octabin covers

- 2 Heavy duty supporting structure on top of the filling station for support of the dosing valve, integration of de-dusting plant and support of metal detector

- Electrical lifting system for closing of smaller bigbags on the bigbag closing position

- LOTO zoning to be able to work with one line while the other line is down due to maintenance or cleaning.