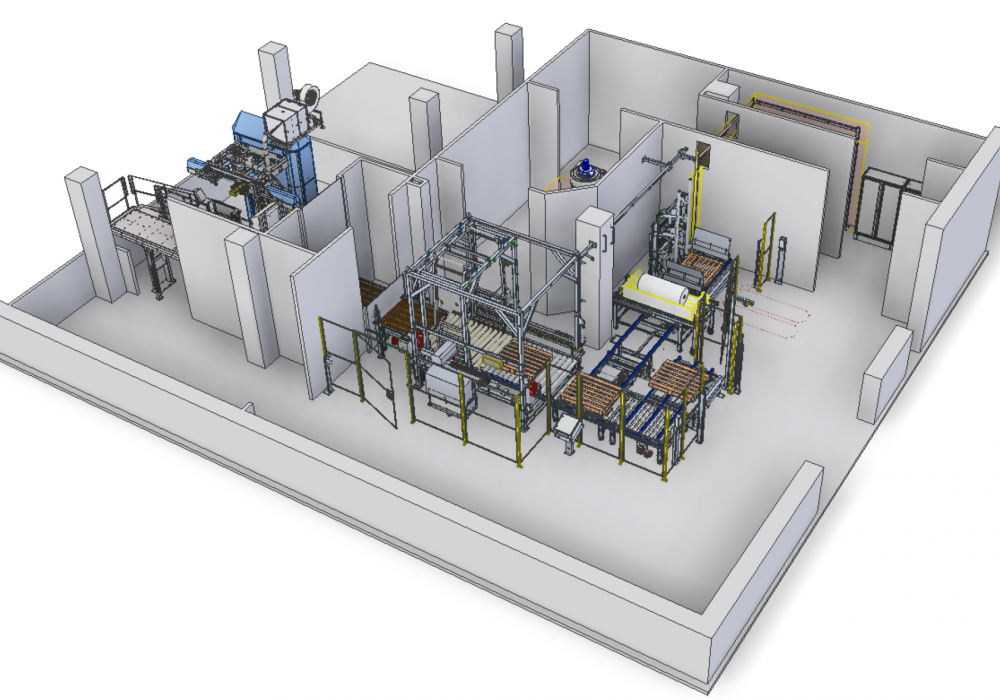

An ultra-clean, high-care bigbag filling installation for a premium babymilk powder producer in Bretagne, France.

An ultra-clean, high-care bigbag filling installation for a premium babymilk powder producer in Bretagne, France.

The project consists of high-care filling, weighing and sealing of bigbags in the clean room. With automated bigbag transport, through an air lock, towards the low care packing area where bigbags are placed on their corresponding pallet. Two high care filling lines with automatic sealing reach an average capacity of 20 bigbags per hour. Pallet intake, PE foil placement and product sampling are an integral part of this challenging project.

The Challenge

The filling process takes place in a cleanroom where pallets are, due to contamination risk, not allowed. Therefore, the filling process is accomplished without positioning bigbags on their pallet. Instead, the bigbag is positioned on a conveyor belt and transported towards the basic care where it is placed on its pallet.

Accessibility and cleanability were major design drivers throughout the entire project as well as material selection and surface finishing of product contact surfaces.

The solution

Delaere developed a sanitary concept to fill products such as (baby) milk powder, starch, cacao and other related products that are typically filled in a cleanroom.

Our concept of pallet-less filling of bigbags in cleanrooms is nowadays considered as a leading industry standard. Read more about this case.

The result

- Accurately filled and stable bigbags - logged and traceable.

- A state-of-the-art filling concept that is flexible enough to pack milk powder into wide range of different bigbags with its corresponding packaging consumables.

- A safe, accurate and truly sanitary filling process where the prevention of contamination risk is our top priority.